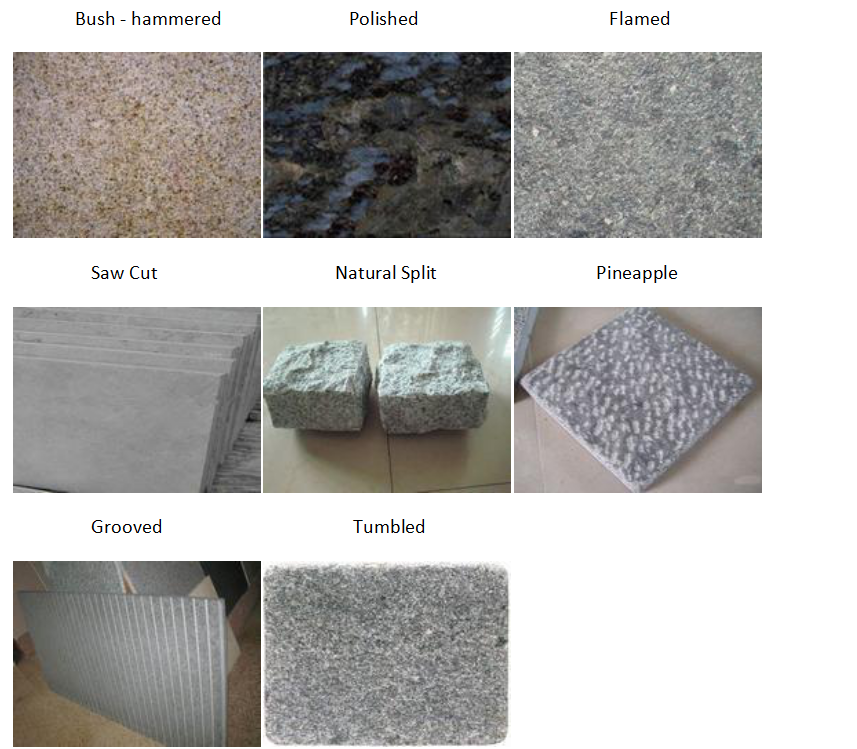

Polish: High shine. The polish may last a long time or may be unstable depending on the type of stone. Granite, marble and limestone are frequently polished, and require varying degrees of maintenance to preserve the shine.

Flamed: Machine cut down the slabs, after high temperature flame barbecue plate on the granite slabs surface, so that more rough stone surface, is not easy to skid, Flaming primarily done to granite.

Rock Face: Rough texture, not as abrasive as flamed. This finish is typically achieved by hand cutting and chiseling at the quarry, exposing the natural cleft of the stone. This finish is primarily done on slate.

Grooved: A worn-down look achieved by brushing the surface of the stone, simulating natural wear over time.

Saw-cut: Matt finish. After initial cutting, the stone is processed to remove the heaviest saw marks but not enough to achieve a “honed” finish. Granite, marble, and limestone can be purchased this way, typically on a special order basis

Tumbled: Smooth or slightly pitted surface, broken rounded edges and corners. There are several methods used to achieve the tumbled look. 20mm thick tiles can be tumbled in a machine, or 3cm tiles can be tumbled and then split, creating two tiles that are tumbled on one side. Marble and limestone are the primary candidates. For a tumbled finish.

Bush Hammered: This rough, textured surface is developed through pounding action on the stone. The degree of roughness is controllable.

Sawn: (Unpolished). It is not advisable to buy this way because: floor polishers do not give as good a polish as factory machine polishers. Many defects are not visible easily before polishing.

Mushroom: In fact, the finish is natural cleft. Just the appearance is like a Mushroom

Filled: When travertine is used for tiles and slabs, it is usually filled with cement or sometimes epoxy, and then polished or honed like any other stone tiles or slabs.

Water jet surface: it is usually done by a high pressure of around 25000 PSI, the surface will become rough and more importantly this finish could restore the color.

Calibration: grind a surface with a high grit material to a uniform surface to maintain the thickness variation.

Gang saw: To grind two sides of the stone surfaces with a high grit material to a uniform specification without producing a reflective surface.

Contact:

Phone: 0086-18159884921

Tel: 0086-592-7628325

Email: info@infinite-gm.com

Add: No. 1515, Xinao Road, Xiangan District, Xiamen, China